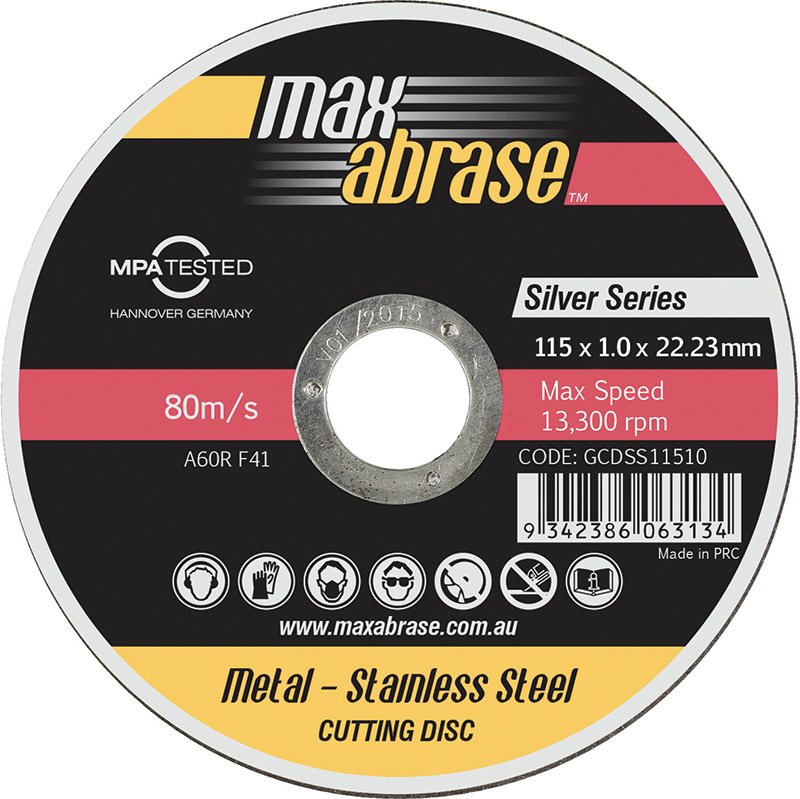

Alpha GCDSS11510 | Cutting Disc 115 x 1.0 mm Silver Series | 1 Buy.. Discontinued

$2.46

$2.24 ex. GST

Search Results:

Search Results:

Cutting discs are used for cutting all types of metal and other dense or non-dense materials like plastic or wood for fast and straight cuts.

Cut-off wheel discs feature a thin profile and a tapered edge that allows them to efficiently slice into forged metal. In practice, these discs are often able to efficiently cut through bolts, plate metal, rebar, and more

Make sure the disc itself is of adequate width otherwise thinner cut-off wheels tend to flex more during the cutting process. This makes them unstable and prone to failure (and sometimes, even shattering) when making deep cuts into thick metal stock. Always use a thicker cut-off wheel for those instances.

Wear rate depends on material hardness, cutting pressure, and correct disc selection.

Sparky Direct supplies cutting discs Australia-wide, offering reliable trade-quality options with convenient delivery.

Cutting discs are packaged securely and delivered via standard courier services.

Unused cutting discs are usually eligible for return in line with the seller’s returns policy.

Warranty coverage varies by manufacturer and generally covers defects in materials or manufacture.

Cutting discs are available both individually and in multi-pack options depending on the product range.

Cutting discs do not require maintenance but should be inspected for damage before use.

Cutting discs should be stored flat in a dry environment to prevent damage and moisture exposure.

Cutting discs can be used for DIY tasks, provided tools are used safely and appropriately.

Yes, excessive pressure or prolonged cutting can cause overheating and reduce disc life.

Metal cutting discs produce sparks, while masonry discs typically produce dust rather than sparks.

Cutting discs are easy to change using the correct tool and following the grinder manufacturer’s instructions.

If damaged, incorrectly used, or oversped, cutting discs can fail, which is why correct selection and inspection are important.

A cutting disc is used with power tools such as angle grinders to cut materials including metal, steel, stainless steel, masonry, and stone.

Some discs are multi-purpose, but using a disc designed for the specific material gives better performance and safety.

The right cutting disc depends on the material being cut, the tool being used, and the required cut quality.

Cutting discs are commonly used during electrical installation work, but electrical work must be carried out by a licensed electrician.

Yes, discs specifically labelled for stainless steel should be used to avoid contamination and ensure clean cuts.

Thin cutting discs provide faster, cleaner cuts, while thicker discs may offer longer life depending on the application.

Cutting discs must match the grinder’s size and maximum RPM rating to be used safely.

Cutting discs are available in a range of diameters and thicknesses to suit different grinders and cutting applications.

Yes, metal cutting discs and masonry cutting discs are designed differently and should not be used interchangeably.

Many cutting discs are manufactured and tested in line with relevant AS/NZS safety and performance standards, depending on the product.

Cutting discs are typically made from abrasive materials bonded with resin and reinforced with fibreglass for strength and safety.

Cutting discs are designed for specific materials, such as metal, stainless steel, aluminium, concrete, brick, or stone, depending on the disc type.